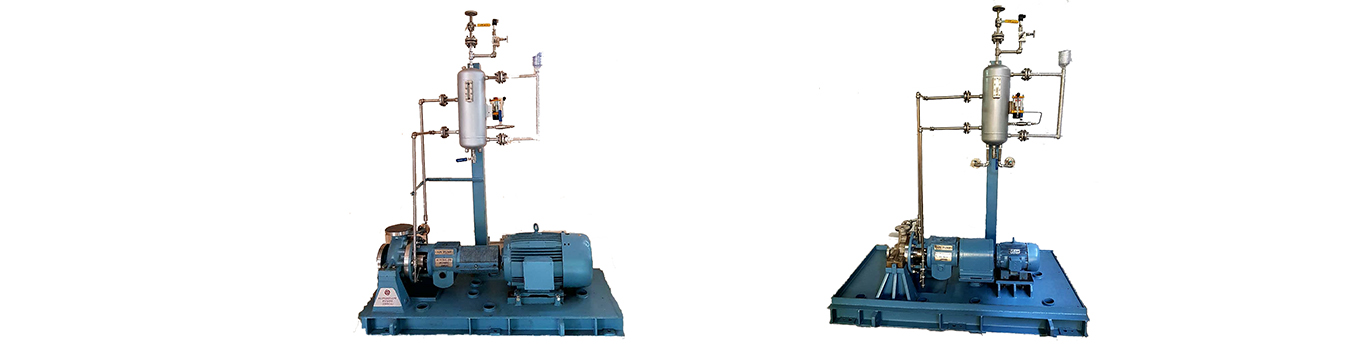

SUPERFLOW API 610 PUMP

Its our great pleasure to introduce our Superflow API Pumps made by using latest technology and softwares. There is general belief among Chemical and Petrochemical industry fraternity about API class of pumps is high cost, as compared to ANSI or ISO class pumps. Yes it is true. However this is not the complete story. They also rec ognize that API pumps are way superior in respect of safety aspects, reliability and life cycle cost. In current sce nario of Petrochemical and Chemical process plants to take full advantage of economy of scales, it is further rec ognized that on account of unforeseen or even frequently planned outages cost industry dearly, and added in vestment is easily recovered by reliability and longer MTBF/MTBM of API Pump.